![]()

Fitting for light gauge stainless steel tubes for ordinary piping: press-type fitting with safety functions. Structure

Product Summary

![[画像]ダブルジョイントイメージ](https://www.benkan.co.jp/img/dp_1.jpg)

Double Press Joint is our well-established press type mechanical joint with safety functions developed for stainless steel piping systems in large scale buildings and factories, and has been on sale since 1991.

In recent years, an increasing number of large facilities, such as government buildings, hospitals, intelligent buildings, and shopping centers have been constructed mainly in the areas around the capital and other major cities.

As the pressure to minimize construction time, there is a rising demand for fittings that requires speedy installation, and high maintainability at construction sites.

In order to meet such needs, our Double Press has all the best of what a mechanical joint can offer: a simple, speedy installation process, and a high cost efficiency almost equal to that of PVC coated steel pipes!

Double Press's unique merit is the trademark safety features which prevent installation errors resulting from insufficient insertion and fittings accidentally left unpressed.

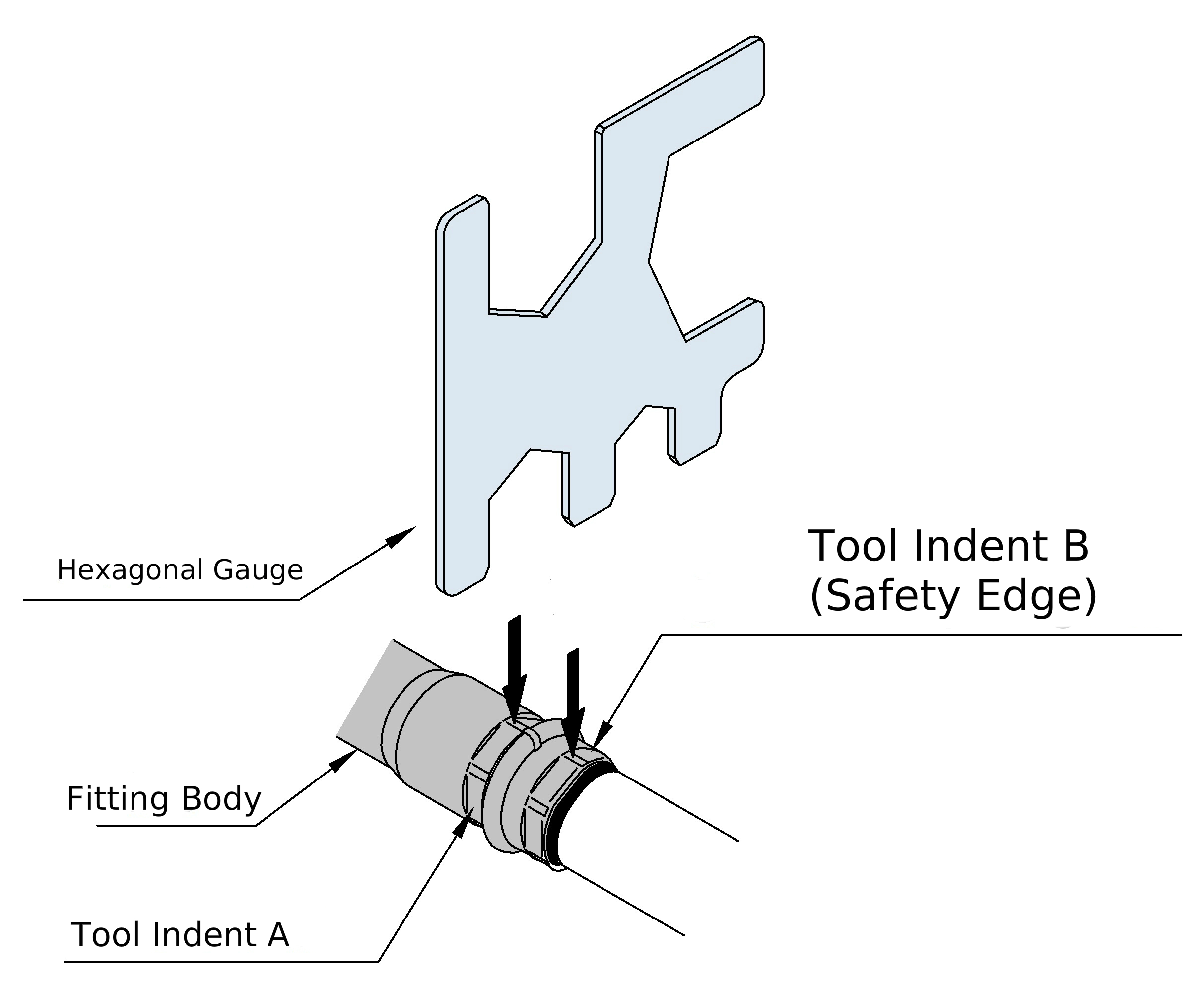

Structure

The joint body is made from 100% stainless steel (defined in Japanese Industrial Standards as SUS304, SUS316), and the heat resistant rubber (IIR: Isobutylene Isoprene Rubber) is used for the seal ring mounted inside the curled part of the joint. Once the pipe is inserted to the adequate depth, and pressed completly by the authorized crimping tool, consistent and sufficient toughness and water-tightness are obtained.

![[画像]ダブルプレスジョイントの締め付け工程](https://www.benkan.co.jp/img/dp_structure02.jpg) * Maximum working pressures for Double Press is 2.0MPa, and for Molco Joint, 1.0 MPa.

* Maximum working pressures for Double Press is 2.0MPa, and for Molco Joint, 1.0 MPa.

![[画像]ダブルプレス構造イメージ](https://www.benkan.co.jp/img/dp_structure01_en.jpg)

Features

Sealing material is attached at the end of 100% stainless steel joint body. The installation is complete by inserting the SU pipe (JIS G 3448) into the joint, and pressing it with the authorized crimping tool. Compare with established construction methods, such as screw fitting and soldering, Double Press can reduce the installation time by 20 %*.

*Based on our experiment results.

- Safety edge compensates for inadequate insertion.

- Safety ring with lumps serves as a reminder if there is any unpressed joints by deliberately causing leakage at the pressure test. These features support the management of installation and maintainance processes at large scale construction sites.

At the pressure test for piping systems after the installation, please check leaks by touching or looking at the joints.

Safety Edge Compensates for inadequate insertion

The edge of Double Press is specially designed for the joint to function without leakage and in accordance with the Japanese Stainless Association Standard (SAS322) even in case that the pipe was not fully inserted before installation. If the pipe is not inserted as far as the minimum acceptable depth (L2), a leak will be detected at the pressure test prior to themal insulation and pipe-bedding processes.

- Even in the case of inadequate insertion of the pipe, as long as no leakage was detected at the pressure test, it provides sufficient pull-out resistance as specified in SAS322.

![[画像]ダブルプレス構造イメージ](https://www.benkan.co.jp/img/dp_feature01_en.jpg)

Safety Ring with Lumps Ensures all joints are pressed

Double Press has a uniquely designed "sealing ring with lumps" which allows to detect any uninstalled joints were left by deliberately causing a leak at the water pressure test.

- The pressure test needs to be conducted prior to thermal insulation and pipe-bedding processes. Please check for leaks by touching or looking at the joints.

Service Life of Sealing Ring

The ring is made from isobutylene isoprene (IIR) rubber, the working temparature must be lower than 80°C. The service life (right) is an estimation based on the results of the accelerated degradation test, originally developped after T.W.Dakin's reaction kinetics theories and Arrehenius's rate equation.

2.303 log K=-E/RT+C

K:Reaction Rate Constant

E:Activation Energy

R:Gas Constant

T:Absolute Temperature

The chart shows the estimated service life of the rubber ring obtained from the formula above. The primary reaction here is rubber degradation. We determined the compression set rate of 50% as criterion for the service life span of rubber ring, with the safety factor of 2.

![[画像]凹凸リング概略図・ダブルプレス管接合部構造](https://www.benkan.co.jp/img/dp_feature02_en.jpg)

Specifications

- Compatible Pipes

- Light gauge stailess steel pipes for ordinary piping (JIS G 3448)

Light gauge stailess steel pipes for water work (JWWA G 115) - Usage

- Cold water, hot water, coolant water, cold/hot water and others

- Unavailable for steam plumbing.

- For use in piping systems for compressed air, ozone, inert gas, pure water, anti-freeze solution, vegetable oil, the requirements may vary, so please contact us for further details.

- Allowable Working Pressure

- 2.0MPa(20.4kgf/?)

- Allowable Working Temperature

- Below 80℃

Certification

-Approved by SPAN (Suruhanjaya Perkhidmatan Air Negara)

NO. SIJIL PENDAFTARAN : SPAN/KP/00736-2010, SPAN/KP/A/00084-2008, SPAN/KP/A/00085-2008

-Approved by Shanghai Municipal Health Bureau(上海市?生局)

Shanghai hygienic administrative license of imported products related to drinking water hygiene safety (上海市?口?及?用水?生安全?品?生行政?可)

Installation

*This is a brief guidance. For further details, please read the installation manual. Please be sure to complete our installation workshop before construction.

|

|

|

|

|

|

For installation of Double Press, do NOT use any tools not authorized by BENKAN corporation, as it may lead to pipe failure, leakage and other accidents.

Electro-hydraulic Press Tools Authorized by Benkan

BPD-08

For small diameters (13Su, 20Su, 25Su).

Requires external power supply.

![[画像]専用締付工具:BPD-08型](https://www.benkan.co.jp/img/double_tools_bpd08.jpg)

BPD-15R

A portable battery-powered model for small diameter (13Su, 20Su, 25Su).

![[画像]専用締付工具:BPD-15R型](https://www.benkan.co.jp/img/molco_tools_bpd15r.jpg)

BPD-11

For larger diameters(30Su, 40Su, 50Su). Requires external power supply.

![[画像]専用締付工具:BPD-11型](https://www.benkan.co.jp/img/molco_tools_bpd11.jpg)

![[チャート]耐熱寿命推定図](https://www.benkan.co.jp/img/dp_feature03_en.jpg)

![[写真]ダブルプレスジョイント施工例1](https://www.benkan.co.jp/img/dp_example01.jpg)

![[写真]ダブルプレスジョイント施工例2](https://www.benkan.co.jp/img/dp_example02.jpg)

![[写真]ダブルプレスジョイント施工例3](https://www.benkan.co.jp/img/dp_example03.jpg)

![[写真]ダブルプレスジョイント施工例3](https://www.benkan.co.jp/img/dp_example04.jpg)

![[写真]ダブルプレスジョイント施工例3](https://www.benkan.co.jp/img/WP_example.jpg)

![[写真]ダブルプレスジョイント施工例3](https://www.benkan.co.jp/img/WP_example2.jpg)

![[写真]ダブルプレスジョイント施工例3](https://www.benkan.co.jp/img/WP_example3.jpg)

![[写真]ダブルプレスジョイント施工例3](https://www.benkan.co.jp/img/WP_example1.jpg)

![[画像]BKジョイント施工要領1](https://www.benkan.co.jp/img/dp_flow1.jpg)

![[画像]BKジョイント施工要領2](https://www.benkan.co.jp/img/dp_flow2.jpg)

![[画像]BKジョイント施工要領3](https://www.benkan.co.jp/img/dp_flow3.jpg)

![[画像]BKジョイント施工要領4](https://www.benkan.co.jp/img/dp_flow4.jpg)

![[画像]BKジョイント施工要領5](https://www.benkan.co.jp/img/dp_flow5.jpg)